Prefabrication

Prefabrication

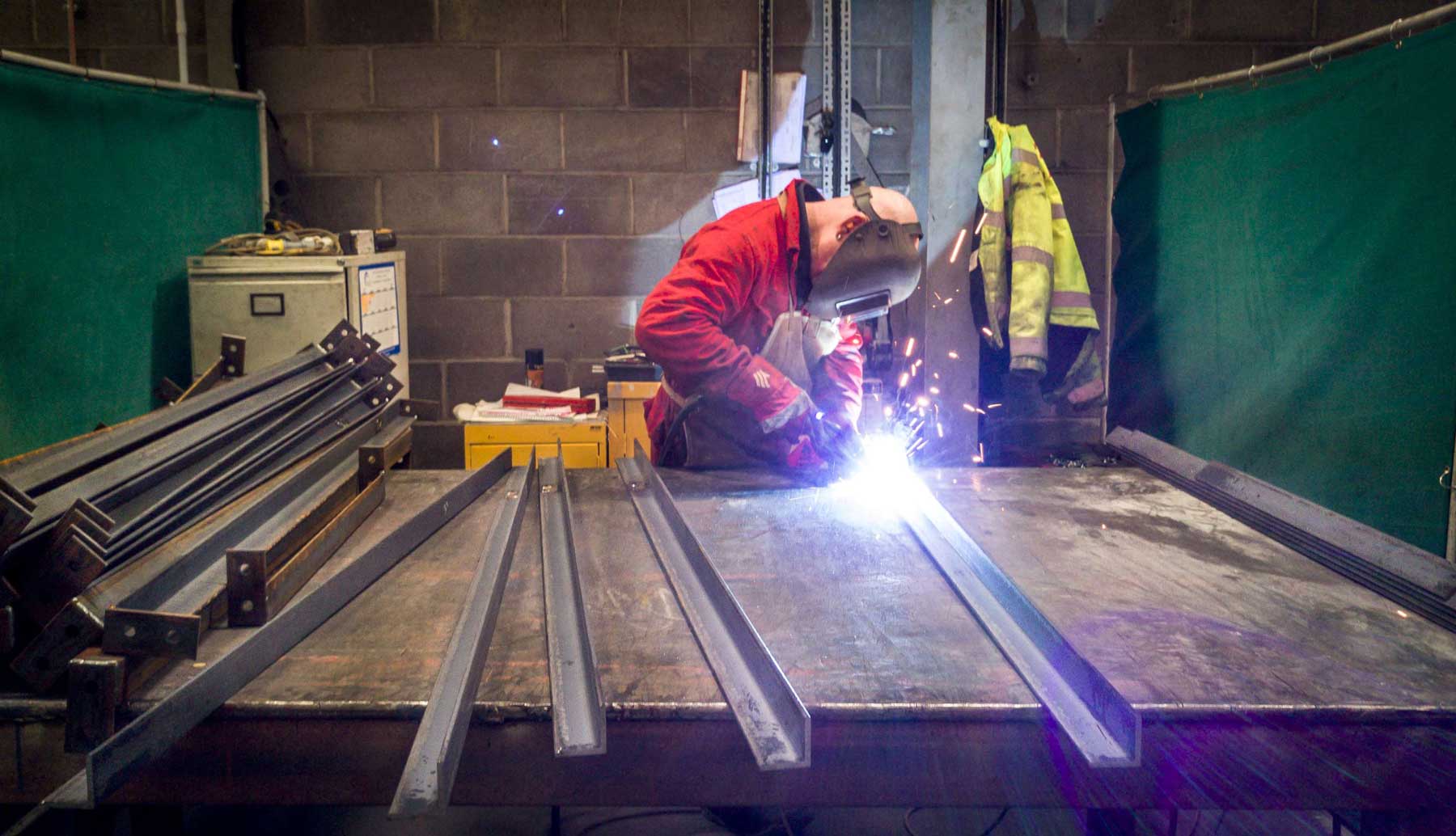

Prefabrication is an important element in construction programmes to reduce risk and minimize disruption to your organisation. It is an area where Klingelt Engineering can add significant value and is a key aspect of our delivery model on all projects.

Klingelt Engineering has a 20,000 sq. ft. wholly owned, purpose-built, prefabrication facility in Stirling.

Advantages

Prefabrication brings with it many advantages over traditional construction methods, including:

- Improved health & safety

- Reduced construction time

- Improved quality

- Lower costs

- Improved sustainability (less waste)

- Consistency and quality control

- Flexibility

Prefab Services

Our prefabrication services include:

- the design and build of complex plant rooms, on skids and pre-clad or fully fitted stand-alone units

- pre-assembled M&E service modules and risers

- a wide range of temporary containerised heating and/or cooling plant rooms for purchase or hire

The Process

The process of prefabrication begins with the design and planning stage. During this stage, the design team creates detailed plans and specifications for the building components that will be prefabricated. This digital engineering process means that the client can get sign off on the building components before we send any engineers to site to install them. Once the design is complete, the components are manufactured/assembled in the controlled factory environment, ensuring that each element is built to the exact specification and meeting the highest quality standards. Once the prefabricated modules have been manufactured, they are transported to the construction site where they are installed.